It's well known that solar panels degrade over time. Most panels decline by about 0.6% per year, while some premium brands like SunPower advertise a lower degradation rate of a mere 0.25 % per year. This level of degradation is normal, but in some cases, the decline is much more severe, suggesting other underlying causes.

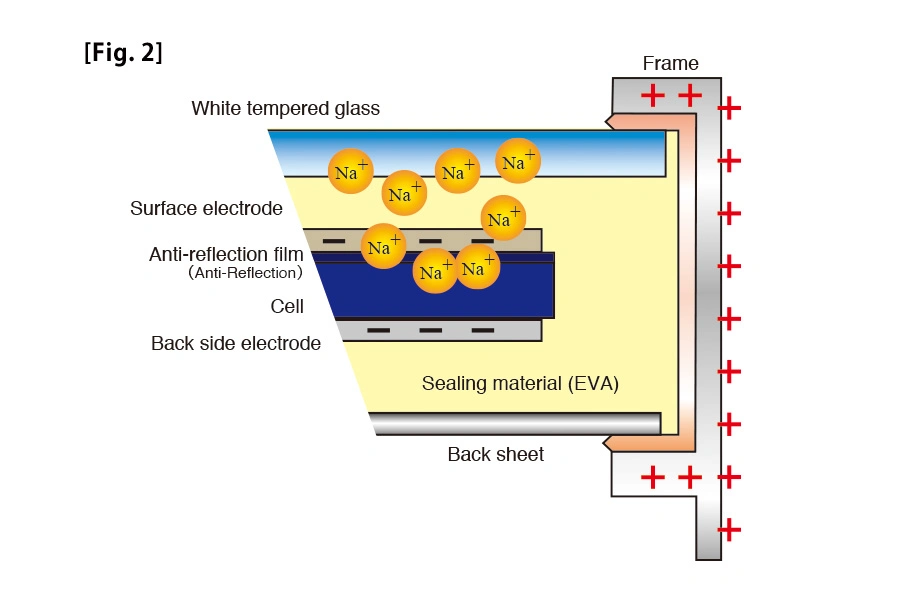

One possible cause is Potential Induced Degradation (PID). PID occurs when ions are drawn from the panel’s frame and migrate into the solar cells, reducing their power output. These ions are attracted by the negative voltage of the solar panels. Ideally, there should be enough insulating material between the cells and the frame to prevent this ion migration. However, in the past, this issue was not well understood, as it only becomes apparent over time. That’s why we are now seeing cases of PID in older panels.

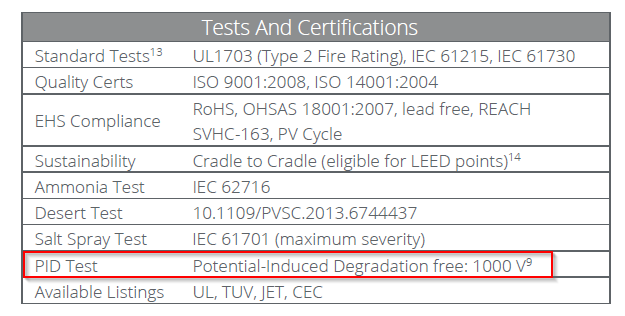

When the problem first emerged, panel manufacturers quickly worked to improve the insulating layer between the frame and the cells, keeping the ions in place. These improved panels are now labeled as ‘PID-free’ in their datasheets.

That said, not all older panels necessarily suffer from PID. The phenomenon mainly occurs in panels with a high negative charge relative to their surroundings. This happens in specific inverter setups with long strings of many panels connected in series. The panels at the end of the string, closest to the negative terminal, are at the highest risk for PID due to their stronger negative voltage.

There are many reasons why solar panels might produce less energy: dirt buildup, damaged cells, or shading, for example. If these causes are ruled out, further investigation is needed. One indicator of PID is a shift in the ratio between the open-circuit voltage (Voc) and the voltage under operating conditions (Vmpp). If this ratio changes significantly over the years, it may suggest PID. Another way to identify PID is by performing a so-called 'I-V curve analysis'.

At this point, the panel manufacturer should be contacted for a more detailed assessment. They may request additional testing to confirm the issue. In principle, PID problems are covered by the manufacturer’s performance warranty.

If a panel is affected by PID, it can be replaced with a ‘PID-free’ panel. However, there are also alternative solutions. By applying a reverse voltage to the string at night (when the sun is down), the ions can be pushed back out of the solar cells and returned to their original layer. This effectively ‘regenerates’ the panel, allowing it to function properly again the next morning.

Devices that generate this reverse voltage are available from companies like Ilumen and Pidbull. These devices consume very little energy—much less than the additional energy they help recover—and operate automatically. However, they need to remain permanently connected to the system. If the panels have already degraded past a certain level, a ‘PID-box’ may no longer be able to restore them.

As one of the longest-standing solar panel installers in the Netherlands, Zonnefabriek has extensive experience with various system issues. Back in 2018 we came across a handful of confirmed cases of PID. However, during our maintenance checks on older solar installations we often find that in fact their actual yield is much higher than we initially predicted. Nevertheless, we always remain vigilant for signs of PID and investigate any suspicious cases.

The panels we've been installing for the last twelve years or so are all guaranteed to be ‘PID-free.’ For this reason, we do not expect PID to be an issue for our customers in the future. However, in recent years many other forms of degradation have been discovered, such as LID (Light Induced Degradation), LeTID (Light and elevated Temperature Induced Degradation) and UVID (Ultra-Violet Induced Degradation). So far, we haven't had any problems with these new issues, but we are of course keeping a close eye on it!